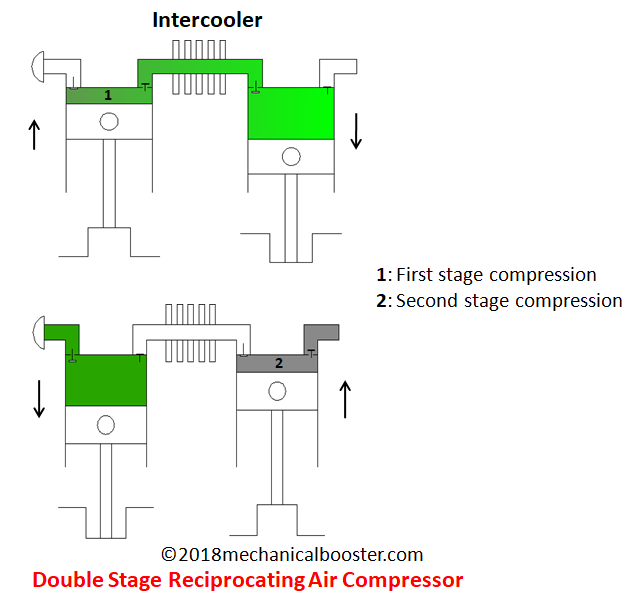

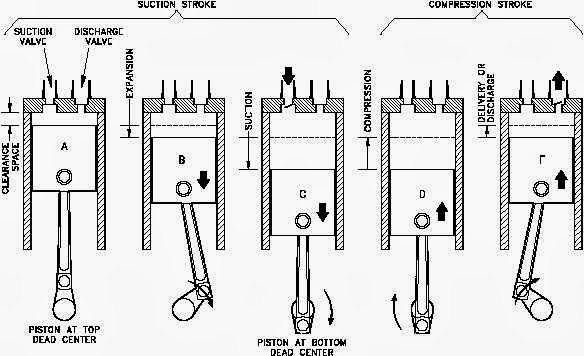

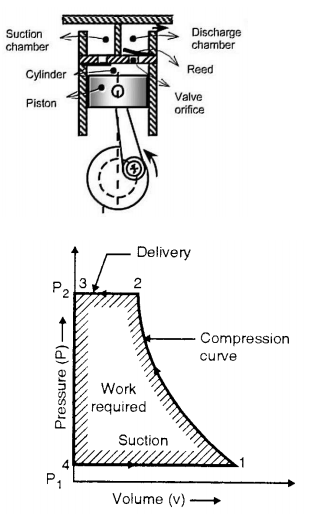

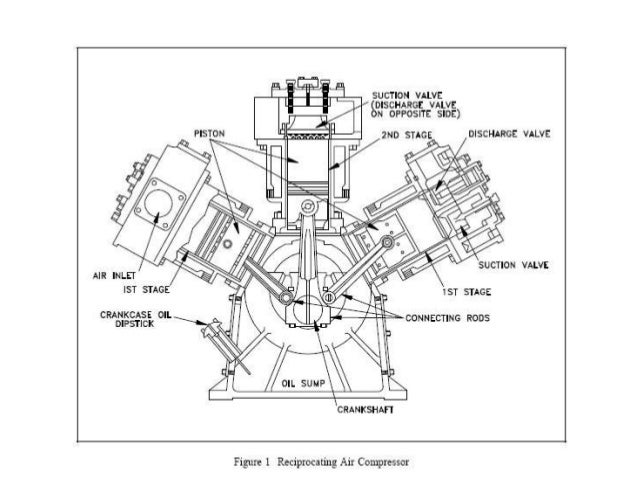

In reciprocating air compressor as the piston moves towards the bdc the air is sucked into the cylinder from the atmosphere and when it moves towards the tdc the compression of the air starts and keeps on going and pressure increases.

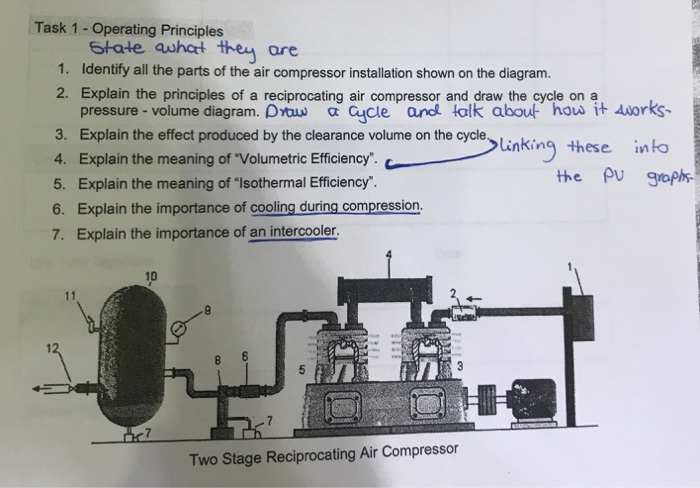

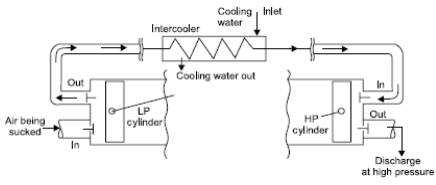

Two stage reciprocating air compressor working principle.

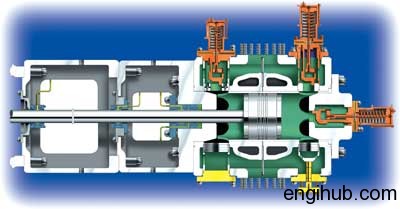

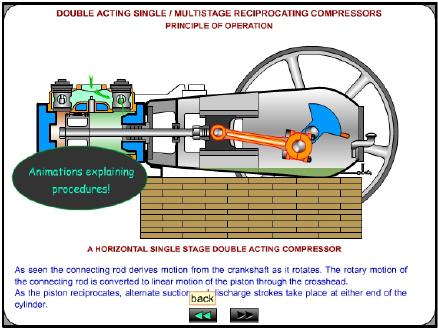

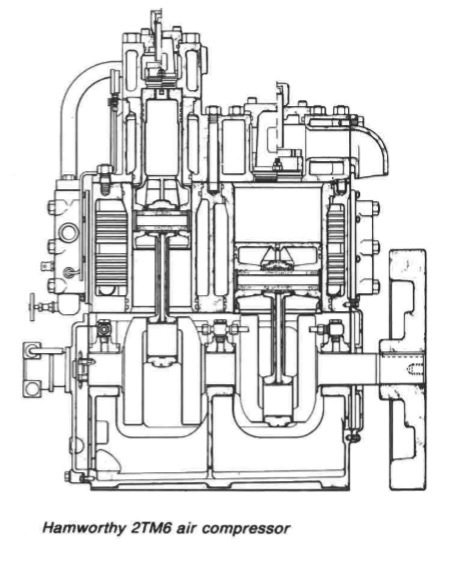

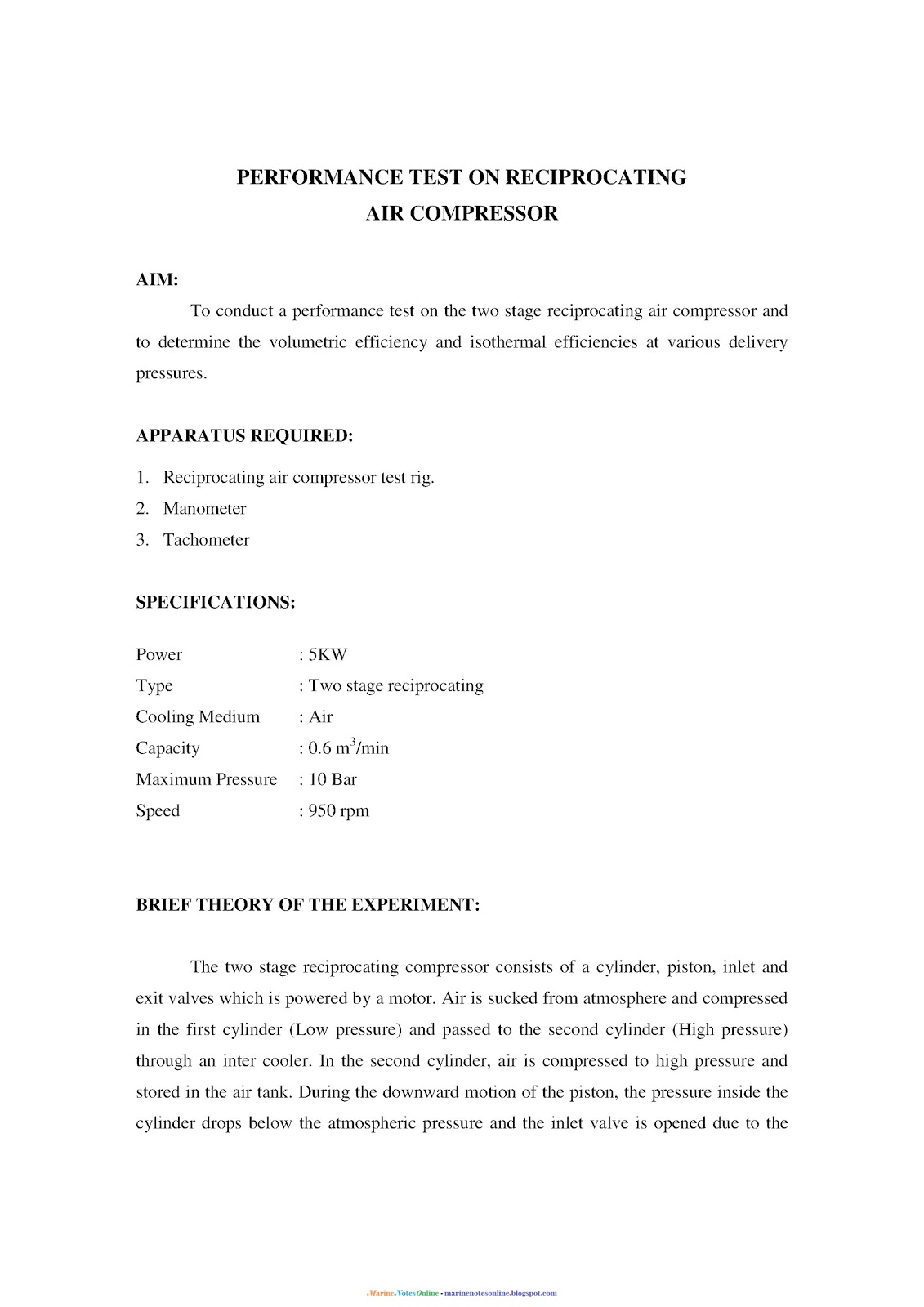

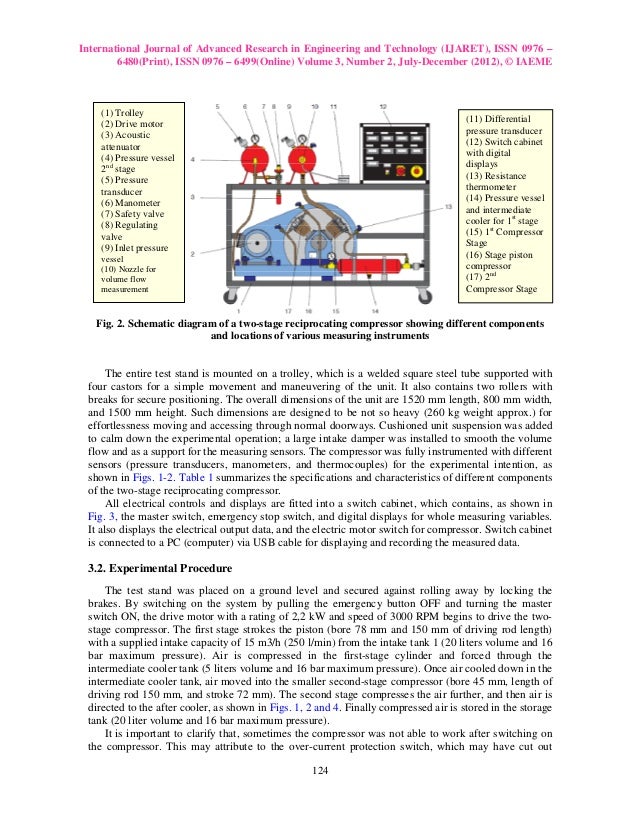

Double stage or two stage reciprocating air compressors consists of two cylinders.

A hand operated tire pump is an example of a simple air compressor.

Click the image to enlarge the simple reciprocating air compressor has a piston which reciprocates inside the cylinder wall and cylinder head.

While straightforward this setup is limited in its efficiency and capacity for delivering high volumes of pressurized air.

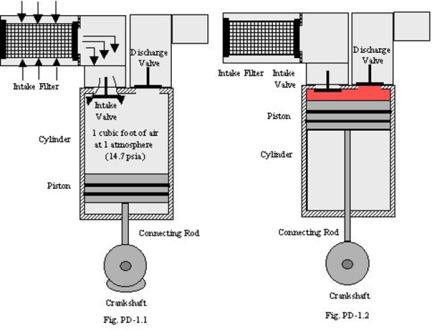

The simplest compressor designs feature a single cylinder chamber arrangement.

So classification will help you better understand the working of the reciprocating air compressor.

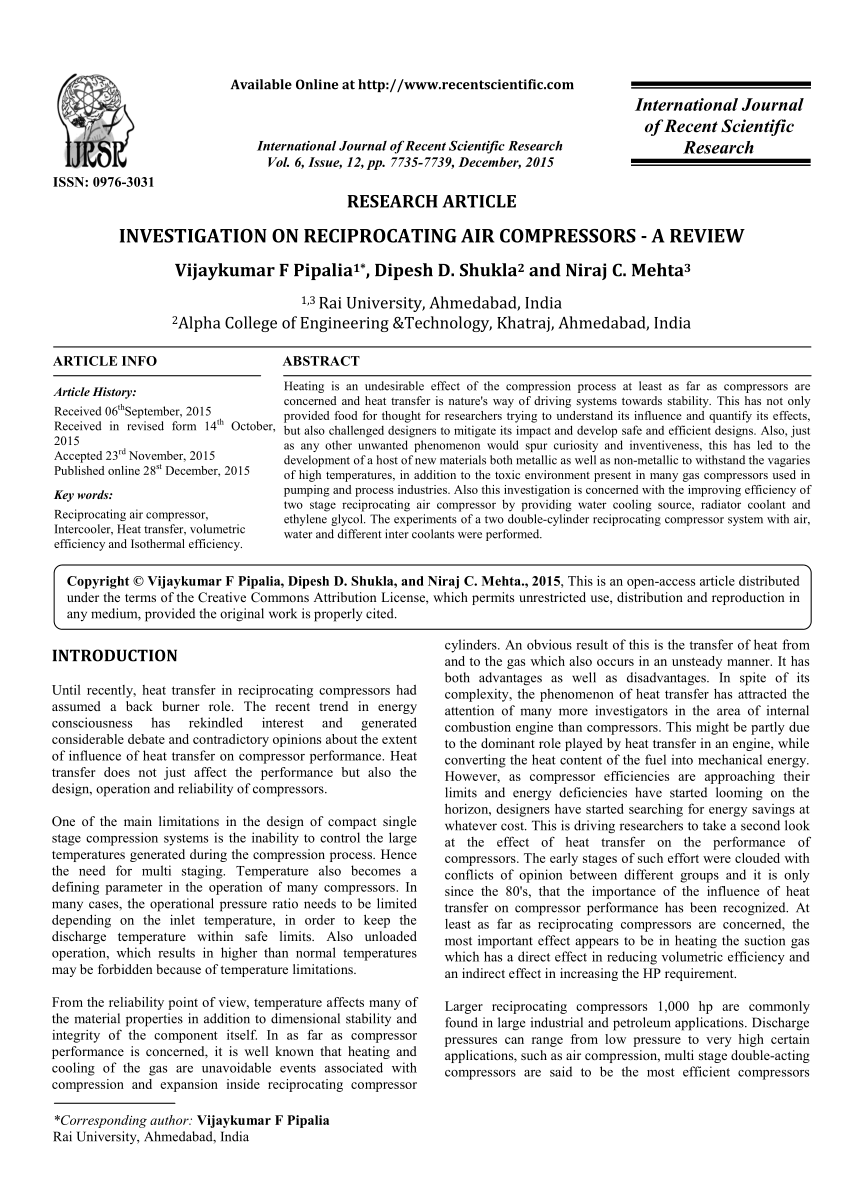

They are much stronger than single stage compressors and can handle more pressure and more capacity.

When piston in a low pressure cylinder is at its outer dead center odc the weigh.

Reciprocating piston compressors use a cylinder to force air into a chamber where it is compressed.

When the tank s pressure reaches its engineered upper limit the air compressor shuts off.

But according to stages the building of discharge pressure is different in each compressor.

The operator then pushes down on t.

Air enters the pump s cylinder as the plunger is raised.

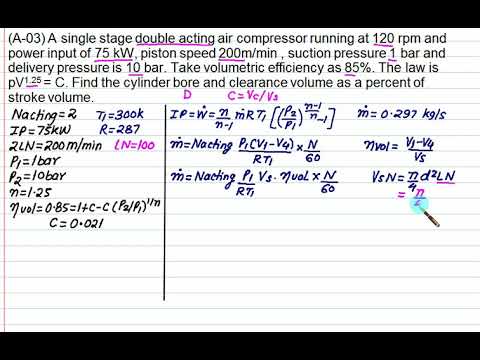

The main difference between single and two stage compressors is the number of times that air gets compressed between the inlet valve and the tool nozzle.

One is called low pressure cylinder and another is called high pressure cylinder.

Two stage air compressors.

Today we re discussing how these compressors work.

In a single stage compressor the air is compressed one time.

With two stage air compressors the air is compressed in two.

To understand the operation of an air compressor let us assume the cycle and indicator diagram for a simple single stage reciprocating air compressor as shown below.

In a two stage compressor the air is compressed twice for double the pressure.

When the pressure increases upto its design limit it pushes the discharge valve to open.

An air compressor is a device that converts power using an electric motor diesel or gasoline engine etc into potential energy stored in pressurized air i e compressed air by one of several methods an air compressor forces more and more air into a storage tank increasing the pressure.

An air compressor takes air at atmospheric pressure and raises it to a higher pressure.

The principle of operation is same in each type.