The thermal conductivity of a material is a measure of its ability to conduct heat it is commonly denoted by or.

Value of coefficient of thermal conductivity of rubber.

Hence the thermal conductivity increases by a few percent in the range 0 to 100 o c.

It is capable of working with solids liquids pastes and powders and can perform both low and high temperature readings.

The thermal conductivity of materials is required for the analysis of thermal resistance networks when studying heat transfer in a system.

Showed lower thermal coefficients than the asphalt rubber mix.

It is not expected that the rubbers are different in their temperature dependent behavior so we may retain the rule of thumb of the may issue.

Please refer to the article thermal conductivity values for other metals and alloys for further information.

The f test is applied to check the linear relationship between thermal conductivity and variables in the mlr model based on the mlr results the f test values are 149 39 183 69 and 124 97 in rubber fine sand rubber medium sand and rubber coarse sand mixtures respectively which are larger than f 0 025 3 41 2 84 corresponding to the.

Again all values in the table are defined at room temperature.

Thermal conductivity is a material property that describes ability to conduct heat thermal conductivity can be defined as the quantity of heat transmitted through a unit thickness of a material in a direction normal to a surface of unit area due to a unit temperature gradient under steady state conditions.

In the second part of the study a heat.

Find linear thermal expansion coefficient α and volumetric coefficient for thermal expansion β at 20 c for different material like brass copper concrete lead silver water and more linear thermal expansion coefficient α at 20 c for rubber is 77 x 10 6 c and volumetric coefficient for thermal expansion β at 20 c is 231 x.

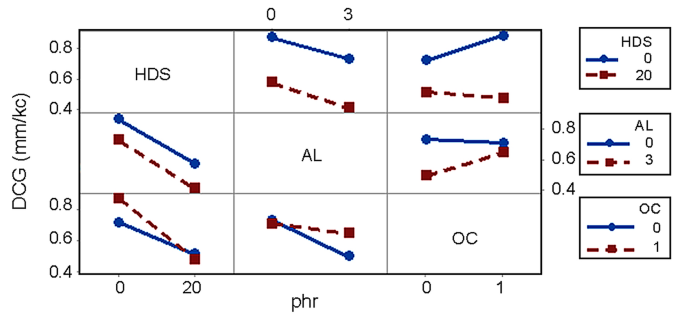

The thermal coefficient values were dependent on material type and method of compaction.

Cork sheets 220 kg m3.

K coefficient of thermal conductivity of the sample a area of the sample in contact with the metallic disc x thickness of the sample t 2 t 1 temperature difference across the sample thickness m mass of the metallic disc c the heat capacity of the metallic disc dt dt rate of cooling of the metallic disc at t 2.

Cork sheets 260 kg m3.

The thermal conductivity coefficients of the basic materials which are used for insulation are given in the table.

This value is taken away from the total thermal resistance for the.